Services

ONE STOP SHOP FOR PRINTING SERVICES

At One Step Print, we are not just your average print company. We are constantly looking for new and exciting ways to diversify and evolve our business, so that we can better serve our clients and stay at the forefront of the industry. Here are just a few of the things we are currently working on

DIGITAL PRINTING

We provide our clients with high-quality, full-colour prints, perfect for everything from business cards to catalogues. Our digital printing process is quick and efficient, allowing us to turn around projects faster and more cost-effectively than traditional printing methods. Plus, our state-of-the-art equipment ensures that every print is precise and vibrant, making your designs truly stand out.

Digital printing is ideal for short-run printing projects, such as business cards, flyers, brochures, posters and more for personalised printing, such as variable data printing and direct mail campaigns. It also offers the flexibility to print on-demand, meaning that you can print only what you need, when you need it, without any waste or excess inventory.

DIGITAL PRINTING

The laser base Digital printing technology by Konica Minolta & Canon comes equipped with the following features:

- ideal for short run digital printing jobs

- Cost effective printing for short run

- Print size upto 13'' x 40''

The Indigo Printing Technology by HP comes equipped with the following features:

- ldeal for short run digital printing jobs

- Achieves printing quality comparable to offset

- 7 colour Ink stations (C, M, Y, K, Lm, Lc, W or cl.)

- Creates true spot colours

The Indigo Printing Machine can be used for printing on a wide variety of media such as :

Textured and Non Textured Paper, Metpet, Metallic, PVC materials upto 350 gsm

Efficiency parameters of the Indigo Printing Machine:

- Can print 160 pages per minute for most image-rich color jobs, significantly

- Most nearest result for offset proofing

- Inks are matt unlike other laser base digital short run machines

- Can print upto 200 LPI

The Indigo & Laser Digital Printing Machine is ideal for printing:

Short run job that needs high-impact text, graphics and colour printing of commercial printing, dummy and prototype of packaging.

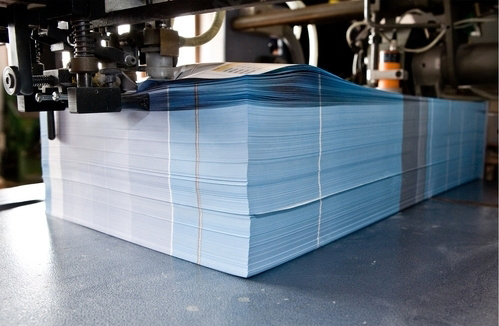

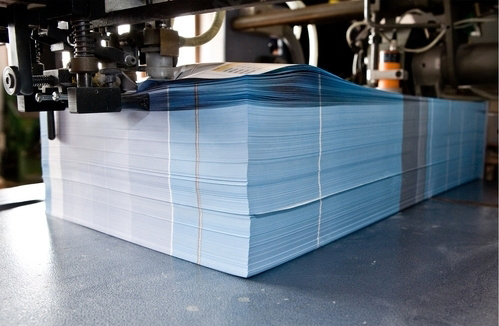

OFFSET PRINTING

Offset printing is known for its high-quality, consistent results and is often used for large- scale printing projects, such as magazines, booklets, catalogues and more. It can also handle a wide range of materials, including different kinds of paper, various cardstock, envelopes and even plastic and sticker sheets.

One of the main advantages of offset printing is that it can produce large quantities of prints quickly and cost-effectively, making it a popular choice for commercial printing & packaging. Additionally, it offers the ability to print with a wide range of colours, including Pantone colours and special metallic inks.

OFFSET PRINTING

PLANNING

- Product Analysis

- Customer Requirements

- Final Paper Engineering

- Job Scheduling

- Departmental Responsibility Sharing

- Correct Costings as per Customer Requirements

- Turnaround Time

- Customer Approvals

PRE-PRESS

- Designing and Layouts

- Final Artwork Making

- Colour Correction

- Job Corrections for any incompatibilities

- Preflight and Processing

- Colour and Digital Profiling

- CTP Using Thermal Plates

PRODUCTION

With years of experience, we are capable of delivering to all client requirements, with high quality printing in minimum possible time. Some of the key facilities available in our production unit include:

- Printing upto 30 x 40 inch

- Paper thickness from 70 - 400 GSM

- 1, 2, 4 & 5 colour with Aqua coater sheet fed offset printing

SPECIALITY SERVICES

- Metallic Foil-on-board Printing

- Drip Off UV Printing

- Invisible Printing

- Scratch and Fragrance Printing

- Fluorescent Printing

POST-PRESS

Post-press is where a printing job comes together, in a raw sheet. Post-press activities are essential for finishing printed materials and preparing them for distribution or end-use. These activities include various processes that enhance the appearance, durability and functionality of the printed materials. Some common post-press processes in offset printing include:

- All types of Automatic Folding

- Automatic Collation of Forms

- Tipping-In and Insertion

- End Paper Pasting

- Automated Case Making

- Packaging & Forwarding

EMBELLISHMENTS

- Spot UV : Gloss, Matt, Abrasive,

Glitter, Bubble, Emboss etc. - Wet Lamination : Matt, Gloss,

Velvet, Laser etc. - Thermal Lamination : Matt, Gloss,

Velvet, Laser etc.

- Varnish

- Multi-Coloured Foil Stamping

- Embossing and Debossing

- Edge Gilding

- Die-Cutting

- Graining

BINDING

- Hard Case Binding:

Round & Square Back - Soft Case Binding

- End Paper Pasting

- PUR Perfect Binding

- Hot Melt Perfect Binding

- Saddle Stitch Binding

- Loop Pin Wire Stitching

- Back to Back Binding

- Centre Thread Sewn

- Wiro Binding

- Spiral Binding